Understanding Air Compressors

Air compressors are versatile devices that convert power into potential energy stored in pressurized air. This process involves compressing air in a storage tank, which can then be released to perform various tasks. By drawing in air through an intake valve, the compressor reduces the volume of air, thus increasing its pressure. Several types of air compressors exist, each designed to fulfill specific requirements, making them essential in various settings, from industrial production to household maintenance.

The mechanics behind air compression typically involve either positive displacement or dynamic displacement techniques. Positive displacement compressors, such as piston and rotary screw compressors, utilize a piston or rotor to compress air into a smaller volume. In contrast, dynamic compressors, like centrifugal air compressors, use high-speed rotating impellers to create a pressure difference that draws in and compresses the air. Understanding these mechanisms is crucial for selecting the appropriate air compressor for your needs.

Air compressors find applications in multiple industries and everyday life. In industrial settings, they are commonly used to operate pneumatic tools, convey materials, and assist in production processes. For instance, air compressors power tools like nail guns, impact wrenches, and spray guns, making them an invaluable resource on construction sites and manufacturing plants. In residential contexts, air compressors are often employed in powering air tools, inflating tires, and cleaning purposes, such as blowing away debris or dust. The ability to provide a reliable source of compressed air makes these devices indispensable for both industrial and household tasks.

In conclusion, understanding air compressors entails recognizing their functionality, mechanics, and diverse applications. By grasping these fundamental concepts, users can make informed decisions about which type of air compressor best suits their needs.

Types of Air Compressors

Air compressors are indispensable tools utilized across various industries for numerous applications, ranging from powering pneumatic tools to inflating tires. Understanding the different types of air compressors available is essential for selecting the right one for your specific needs. The most common types include reciprocating, rotary screw, and scroll compressors, each offering unique features and advantages.

Reciprocating air compressors, also known as piston compressors, operate by using a piston driven by a crankshaft within a cylinder. This type of compressor is renowned for its high pressure output and efficiency, making it a popular choice for both commercial and residential applications. They are available in single-stage and two-stage configurations, enabling varied pressure levels and capacities depending on the project requirements. Reciprocating compressors are ideal for users who need portability or are operating in smaller workspaces.

Rotary screw compressors, on the other hand, utilize two interlocking helical screws to compress air, delivering a continuous and reliable air supply. This type is particularly favored in industrial environments where high volumes of compressed air are required. Rotary screw compressors boast lower maintenance needs and quieter operation compared to reciprocating models, making them well-suited for continuous use. They are often employed in manufacturing and large-scale applications, where uptime is critical.

Lastly, scroll compressors work through two spiral elements, one fixed and one orbiting, facilitating smooth and efficient air compression. These compressors are quieter and have fewer moving parts, resulting in less wear and tear over time. They are commonly used in HVAC systems and refrigerants due to their compact size and energy efficiency. For those requiring a reliable and low-maintenance air compression solution, scroll compressors may be the best fit.

In conclusion, selecting the right type of air compressor hinges on understanding their distinct characteristics and applications. By evaluating the specific pressure, volume, and operational needs, individuals and businesses can make informed choices that deliver efficiency and reliability.

Determining Your Air Compressor Needs

Choosing the right air compressor begins with a clear understanding of your specific needs, primarily influenced by the intended application. The first key factor to consider is the desired airflow measured in Cubic Feet per Minute (CFM). Different tasks require varying airflow rates; for instance, using pneumatic tools like nail guns or impact wrenches typically necessitates a higher CFM rating. It is crucial to assess the requirements of the tools you plan to use, as an insufficient CFM can lead to underperformance and inefficiency in operations.

Another vital aspect is the pressure measured in Pounds per Square Inch (PSI). Many tools have a minimum PSI requirement for optimal performance, and selecting a compressor that meets or exceeds this specification is critical. For light-duty tasks, you might find lower PSI ratings adequate, but for heavy-duty applications, a compressor capable of delivering higher PSI is essential. When researching models, ensure you note the PSI ratings in relation to your tools to avoid investment in an inadequately powered compressor.

In addition to airflow and pressure, the nature of the tools and tasks will play a significant role in your air compressor selection. Tasks such as spray painting, sandblasting, or operating pneumatic machinery often require sustained pressure and airflow. As such, a larger compressor with a higher tank capacity might be necessary to accommodate ongoing demands. Conversely, for sporadic household tasks, a smaller, portable unit may suffice. Understanding the intended applications, frequency of use, and specific tool requirements will guide you in determining an appropriate air compressor that aligns with your operational needs and enhances overall efficiency.

Portable vs. Stationary Compressors

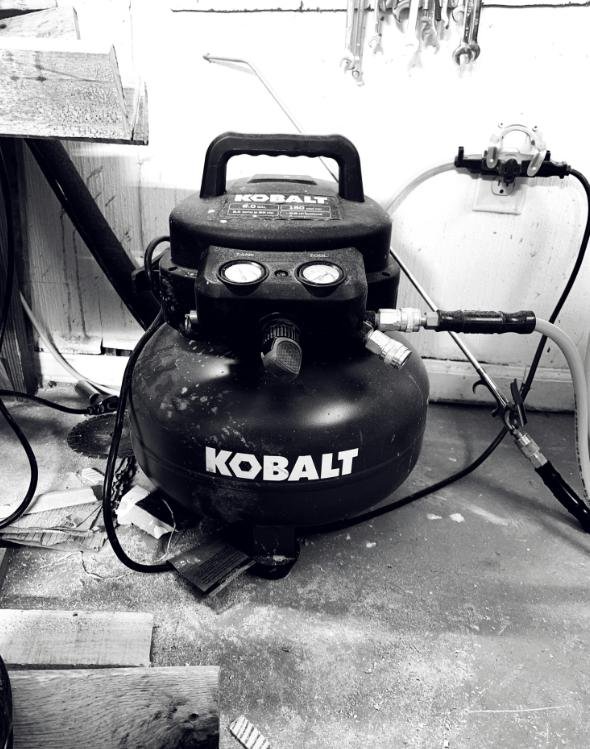

When selecting an air compressor, understanding the differences between portable and stationary models is essential for choosing the right equipment for your needs. Portable air compressors are designed for easy transport, making them ideal for tasks that require mobility. They typically feature a lightweight construction and are powered either by electricity or gasoline, allowing them to be used in various locations. These compressors are particularly beneficial for home improvement projects, outdoor applications, and even automotive repairs, where convenience and accessibility are paramount.

On the other hand, stationary air compressors are intended for fixed installation in a specific location such as a garage, workshop, or industrial site. These units tend to be larger, more robust, and capable of delivering higher air pressure and volume, making them suitable for heavy-duty applications. They are favored in professional settings where consistent air power is necessary, such as body shops, manufacturing plants, and construction sites. However, the type of installation required may necessitate additional space and strategic planning in terms of layout.

When considering which type of air compressor to invest in, it is crucial to evaluate your specific requirements. For infrequent use or tasks that require mobility, a portable air compressor might be the better choice, providing flexibility and ease of use. Conversely, if your operations demand a steady and reliable air supply for extended periods, a stationary air compressor is likely the more suitable option. Ultimately, the decision should take into account factors such as space availability, the frequency of use, and the specific tasks you intend to perform, ensuring you select an air compressor that effectively meets your demands.

Key Features to Consider

When selecting the right air compressor, several key features should be examined closely to ensure optimal performance and suitability for your specific needs. One of the primary considerations is the motor size, as it directly influences the compressor’s capacity and efficiency. A larger motor typically provides higher output, making it suitable for more demanding tasks, while a smaller motor may suffice for light-duty applications.

Another crucial factor to consider is the tank size. A larger air tank can store more compressed air, allowing for longer operation times between refills. This is particularly advantageous for tasks that require continuous airflow, such as spray painting or sandblasting. Conversely, smaller tanks are more portable and may be ideal for intermittent use, thereby reducing the overall weight and size of the unit.

The noise level of the air compressor is also an important consideration, especially for residential or commercial settings where excessive noise could be an issue. Compressors with quieter operation are generally preferred to minimize disturbances, particularly for prolonged periods of use. Investing in a quieter model can lead to a more pleasant working environment.

Additionally, the power source is a vital determinant in your choice. Electric air compressors are often favored for indoor use due to their ease of use and reduced emissions. In contrast, gas-powered models are more suitable for outdoor projects or remote job sites where electricity may not be readily available. Each power source has its advantages and directly impacts the compressor’s portability and functionality.

Lastly, consider the maintenance requirements associated with the air compressor. Some models may necessitate regular oil changes or filter replacements, while others offer oil-free operation that minimizes upkeep. Understanding these maintenance demands can save time and enhance the longevity of your compressor, providing greater overall value.

Budgeting for Your Air Compressor

When considering the purchase of an air compressor, establishing a budget is an essential first step. Air compressors are available in a wide range of prices, influenced by their type, size, capacity, and brand reputation. Generally, homeowners can expect to pay between $100 and $500 for smaller models, such as portable or pancake compressors, which are suitable for light-duty tasks, such as inflating tires or powering small pneumatic tools. If you require a more robust unit for professional or heavy-duty applications, the price can escalate significantly, ranging from $500 to over $3,000 for larger industrial-grade compressors.

In addition to the initial purchase price, it is vital to consider ongoing operational costs, which include electricity consumption and maintenance. Investing in a more energy-efficient air compressor may reduce these costs over time, translating to significant savings. Furthermore, while used compressors may appear to be cost-effective options at first glance, be aware of potential maintenance expenses and the lifespan of the unit.

Warranties play an important role in budgeting for your air compressor. A strong warranty can provide peace of mind, especially for substantial investments. Typically, warranties range from one to five years, depending on the manufacturer and model. It is crucial to read the terms carefully, as they may cover different components, with some plans including lifetime coverage for certain parts. Before making a purchase, it is also beneficial to read customer reviews, which can offer insights on the overall reliability and performance of the compressor.

Finally, it is advisable to shop around, comparing prices across different retailers while also considering the product’s quality and features. Many manufacturers offer seasonal discounts or promotions that could further enhance value. In conclusion, developing a well-rounded budget for your air compressor entails factoring in both purchase price and long-term costs, ensuring that the final choice aligns with your financial considerations while meeting quality standards.

Safety Considerations

When selecting and operating an air compressor, safety is paramount. Proper understanding of safety features and the use of appropriate protective equipment can significantly reduce the risk of accidents and injuries during use. Air compressors, while highly useful, can pose various hazards, including high-pressure air escapes, electrical risks, and noise pollution. Therefore, awareness and implementation of safety measures are essential.

Most modern air compressors are equipped with several safety features designed to protect operators. These can include automatic shutoff mechanisms that engage when the tank pressure exceeds safe limits, pressure relief valves that release excess pressure, and thermal overload protection to prevent overheating. Familiarizing oneself with these safety features, along with the manufacturer’s instructions, is crucial for safe operation.

In addition to built-in safety features, the use of personal protective equipment (PPE) should not be overlooked. Essential PPE may include safety goggles to protect against airborne debris, heavy-duty gloves to prevent cuts and bruises, and hearing protection to mitigate the effects of noise generated by the compressor. These safety measures are vital for creating a safe working environment when utilizing air compressors for various tasks.

Best practices should also be adopted to enhance safety. These include establishing a clear work area, ensuring proper ventilation, and regularly inspecting the equipment for wear and tear. Operators should be trained in the correct methods of using air compressors and be mindful of the potential dangers involved. By emphasizing safety considerations, individuals can effectively minimize risks while benefiting from the capabilities of air compressors.

Maintenance and Care

Proper maintenance is essential for ensuring the longevity and efficiency of air compressors. Regular upkeep not only enhances performance but also minimizes the likelihood of costly repairs. One primary maintenance task involves checking and changing the oil at suggested intervals, as this is crucial for optimal lubrication. If the air compressor is oil-based, it is important to maintain the correct oil level to prevent overheating and damage to internal components.

Another key aspect of maintenance is regularly inspecting and replacing air filters. Clogged filters can reduce airflow and pressure, leading to diminished performance. Depending on the usage frequency, filters should be cleaned or replaced every few weeks to maintain their effectiveness. Additionally, keep an eye on the compressor’s hoses and fittings for any signs of wear or leaks that could affect performance.

Cleaning is equally important in maintaining an air compressor. Dust and debris can accumulate in the intake and exhaust areas, obstructing airflow. Routine cleaning of these components helps to keep the compressor operating at peak efficiency. Furthermore, drain the moisture from the air tank regularly to prevent rust buildup and to eliminate potential obstructions that can reduce the compressor’s efficiency.

Troubleshooting common issues is another vital part of air compressor care. If the compressor fails to start or runs inconsistently, one should check the electrical connections and ensure the pressure settings are correctly configured. Listening for unusual sounds during operation can provide insight into potential mechanical issues, allowing for timely interventions before they escalate into serious problems.

In summary, adhering to a regular maintenance routine, which includes oil level checks, air filter replacement, thorough cleaning, and attentive troubleshooting, is critical for ensuring that an air compressor operates efficiently and has a prolonged lifespan.

Conclusion and Final Tips

Choosing the right air compressor is a substantial decision that can significantly impact your project outcomes, efficiency, and overall satisfaction. Throughout this guide, we discussed various factors to consider when selecting an air compressor, such as the type, size, power requirements, and intended applications. Each of these aspects plays a vital role in ensuring you select a machine that meets your specific needs.

As potential buyers navigate their options, it is crucial to reflect on the tasks they intend to accomplish. For instance, individuals working on large-scale construction projects might require a more powerful and robust model, while casual DIY enthusiasts may find that a smaller, portable compressor suffices. Understanding your primary uses will help you identify the necessary specifications and features, such as pressure and tank capacity.

Moreover, exploring the various types of compressors available—whether they be reciprocating, rotary screw, or diaphragm—will aid in making an educated decision. Each type comes with its advantages and disadvantages, influencing not only performance but also longevity and maintenance requirements. Therefore, it is beneficial to weigh the pros and cons of each option thoroughly.

Lastly, one essential tip for prospective buyers is to take their time. Rushing the purchase can lead to regrets, as it might result in choosing an air compressor that does not align with one’s intended usage. Carefully assessing your specific needs, performing thorough research on different models, and gathering insights from reliable sources can guide you toward making a well-informed selection. Remember that investing in the right air compressor not only supports your immediate projects but also sets you up for long-term success in various applications.